Whether you are on your day cruiser, or a giant cargo ship, you should never head to sea without a bilge pump. A bilge pump is a crucial piece of safety equipment that plays a vital role in keeping your vessel afloat.

But what are bilge pumps and how do we know which ones we need?

In this article we are looking at bilge pumps and systems with a particular focus on our specialty, manual diaphragm bilge pumps. We will explore the importance of manual bilge pumps, their various types and features, installation and maintenance tips, and frequently asked questions to help you make informed decisions regarding their usage.

Whether you’re a seasoned sailor or a novice boat owner, understanding manual bilge pumps is crucial for ensuring the safety and integrity of your vessel. So, let’s dive in and explore the world of manual bilge pumps!

What is a bilge?

The bilge is the lowest part of a ship or boat, where the bottom curves up to meet the sides.

As it is the lowest part, it is also where any water that has entered the boat will accumulate, hence the term bilge water.

This area is prone to leaks, can collect rainwater and wave splashes over the side of the boat, which left unattended, can damage the boat, cause a bad smell on board and even cause it to sink.

What is a bilge pump?

A bilge pump is a device that is used to remove unwanted water from the bilge, the lowest part of a boat’s hull. It is an essential safety tool regardless of boat size or type, that helps prevent flooding and maintains the vessel’s buoyancy.

There are two common types of bilge pumps

- Electric Bilge Pumps

- Manual Bilge Pumps

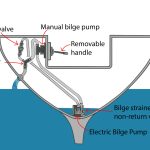

The diagram above shows how a basic bilge pump system may be set up with both an electric and a manual bilge pump. The manual bilge pump can be easily accessed from the cockpit using the removable handle, allowing quick and easy clearing of the bilge without the use of power. While the electric bilge pump may be on a manual switch or automatic on/off switch that activates depending on bilge water levels.

In this feature, we are going to be talking specifically about manual bilge pumps.

What is a Manual Bilge Pump?

Manual bilge pumps are hand-operated pumps that remove water from a vessel’s bilge. They normally comprise of a pump, handle, inlet hose with a strainer and nonreturn valve, and outlet hose.

Manual bilge pumps are commonly installed to work alongside electric bilge pumps and are to be used in emergency situations when other methods, such as electric pumps or onboard drainage systems, may fail or be unavailable.

By manually operating the pump, water can be efficiently discharged overboard, keeping the boat afloat and preventing damage in even the most severe situation.

Manual bilge pumps also offer a quick, efficient and quiet way of emptying the bilge on larger vessels without the need for power. They can also completely empty the bilge where electrical centrifugal pumps cannot due to priming requirements.

Types of Manual Bilge Pumps

There are several types of manual bilge pumps available, each with its unique characteristics and advantages. Let’s explore some of the common types:

Diaphragm Hand Pump

The diaphragm hand pump is a popular choice among boat owners due to its efficiency and ease of use. It features a flexible diaphragm that creates suction and pressure on alternating strokes to move water. Diaphragm bilge pumps are positive displacement pumps, so they are much better at pumping water uphill than centrifugal pumps.

An advantage of diaphragm pumps is that they can run dry, and do not require priming, whereas centrifugal pumps will get damaged. This allows diaphragm pumps to remove all the water from the bilge whereas electric pumps will commonly leave some behind due to their primer requirements.

Diaphragm pumps also have less trouble moving water up. Where small centrifugal pumps may struggle to remove water from deep bilges, this is not an issue for a diaphragm pump.

A feature that makes this type of pump very suitable for bilge water is that it is capable of handling both water and small debris which often can collect in a boats bilge. Pump International bilge pumps are designed with large inlet and outlet ports allowing them to pass solids up to —mm.

Shop our range of diaphragm manual bilge pumps

Piston Hand Pump

Commonly seen on smaller boats, kayaks or tenders, a piston hand pump operates by using a piston and cylinder mechanism to draw water into the pump and expel it through an outlet.

They most commonly do not require installation or fitting, and their slim design allows for easy portability making them convenient for pleasure craft use as they can be easily stored in boat lockers and bought out when required.

Rotary Hand Pump

The rotary hand pump utilizes a rotary motion to move water. It consists of gears or impellers that rotate within the pump housing, creating a pumping action.

This type of pump is particularly useful for transferring larger volumes of water quickly. However, due to the nature of impellers, these pumps require more maintenance and are more prone to failure than diagram pumps and piston pump.

Choosing the Right Manual Bilge Pump

There is no one-size-fits-all solution when it comes to selecting the best bilge pump or pumps for your boat. But, selecting the appropriate manual bilge pump for your vessel is crucial to ensure effective water removal when needed. Consider the following factors when choosing a manual bilge pump:

Boat Size and Type

The size and type of your boat will determine the pumping capacity required. Larger boats may require more powerful pumps to handle higher volumes of water.

Pump Capacity

Determine the amount of water the pump can handle per minute or hour. Consider your boat’s needs and the potential water ingress you may encounter.

Ease of Installation

Look for pumps that are easy to install and integrate into your boat’s existing bilge system. Consider the available space and any specific installation requirements.

Pumps such as our SD60 come ready for use as a bilge pump, with fittings for under deck mountings, fully adjustable ports, and body mountings allowing for 96 mounting positions.

Durability and Reliability

Choose a pump made from high-quality materials that can withstand the harsh marine environment. Ensure that the pump is resistant to corrosion and designed for longevity.

Maintenance Requirements

Check the maintenance requirements of the pump. Opt for pumps that are easy to clean and maintain, as regular upkeep is essential for optimal performance.

Also consider the availability of spare parts, such as diaphragms and handles, as these are serviceable parts that can wear out over time.

Tips on the installation of a Manual Bilge Pump

Proper installation of a manual bilge pump is vital to ensure its efficiency and functionality, if you are unsure, we highly recommend seeking the guidance of an expert.

Here are some tips for a successful installation:

Identify the Ideal Location

Determine the best location for the pump in your boat’s bilge area. It should be easily accessible and not interfere with other onboard equipment. Often manual bulge pumps are fitted beneath the deck and in the cockpit of a vessel, so that the pump does not obstruct movement, with a removable handle that can be inserted for use when required.

Gather the Necessary Tools

Prepare the required tools for installation, such as a drill, screwdriver, hose clamps, and sealants.

Secure the Pump

Attach the pump securely using brackets or mounting plates. Ensure a stable installation to prevent vibrations or dislodgment during operation.

Connect the Hoses

Connect the pump’s inlet and outlet hoses. Use appropriate hose clamps to secure the connections and prevent leaks.

Create a Discharge Path

Establish a clear discharge path for the pumped water. Ensure that it leads directly overboard and does not recirculate back into the bilge.

Test the Pump

Once installed, test the pump by manually operating it. Verify that water is being efficiently removed and discharged overboard.

Maintenance and Care

Proper maintenance and care are essential to keep your manual bilge pump in optimal condition. Follow these guidelines for effective pump performance:

Regular Inspection

Regularly inspect the pump for any signs of damage, wear, or corrosion. It is a great idea to add this maintenance to your annual winterizing or maintenance plan.

Replace any worn-out parts or components promptly.

Cleaning and Flushing

Clean the pump and hoses regularly to remove any debris or obstructions that may affect its performance. Remember to pay attention to the strainer or filter inside the bilge as this can become clogged with debris over time.

Flushing with fresh water helps prevent the buildup of salt and contaminants.

Check Seals and Connections

Ensure that all seals and connections are tight and free from leaks.

Replace any damaged seals or hoses to maintain a watertight system.

Operational Testing

Periodically test the pump by manually operating it to ensure its functionality.

This test also helps identify any potential issues before they become critical.

Emergency Preparedness

Have a backup plan in case your electrical and manual bilge pump fails.

Consider carrying spare parts, such as seals or diaphragms, and a even backup manual pump for emergency situations.

FAQs About Manual Bilge Pumps

FAQ 1: How does a manual bilge pump work?

A manual bilge pump works by using manual force to create suction and pressure, allowing water to be drawn into the pump and discharged overboard. It typically features a handle or lever that is manually operated to initiate the pumping action.

FAQ 2: Can a manual bilge pump handle large amounts of water?

While manual bilge pumps are efficient at removing water, their pumping capacity may be limited compared to electric pumps. However, they can still handle significant amounts of water if operated continuously and with sufficient effort.

FAQ 3: Is it necessary to have a manual bilge pump on board?

Having a manual bilge pump on board is highly recommended for all boats and watercraft. It serves as a crucial backup system in case of power failures, pump malfunctions, or emergency situations where immediate water removal is necessary.

FAQ: Does a manual bilge pump replace the need for an electric bilge pump.

No. While having only a manual bilge pump may be suitable for small vessels such as dinghies and kayaks, on larger boats, it is recommended that a manual bilge pump be used in tandem with an electric bilge pump system.

FAQ 4: How often should I test my manual bilge pump?

It is advisable to test your manual bilge pump regularly to ensure its proper functionality. Perform a manual operation test at least once a month, and before each boating season, to identify any potential issues and ensure reliable performance.

FAQ 5: What are the signs of a malfunctioning manual bilge pump?

Signs of a malfunctioning manual bilge pump include difficulty in creating suction or pressure, leakage around seals or connections, unusual noises during operation, or a decrease in pumping capacity. If you notice any of these signs, it’s essential to inspect and repair the pump promptly.

FAQ 6: Can I use a manual bilge pump for purposes other than water removal?

While manual bilge pumps are primarily designed for water removal, they can be repurposed for other applications where fluid transfer is required. However, it is crucial to ensure compatibility and consider the pump’s limitations and specifications.

Conclusion

Manual bilge pumps are invaluable tools for maintaining the safety and integrity of your boat or watercraft. By understanding their functionality, choosing the right pump, and ensuring proper installation and maintenance, you can confidently navigate the waters, knowing you have a reliable water removal system in place. Remember to test your manual bilge pump regularly and have a contingency plan in case of emergencies. Stay safe, stay prepared, and enjoy your boating adventures!